2023-06-23

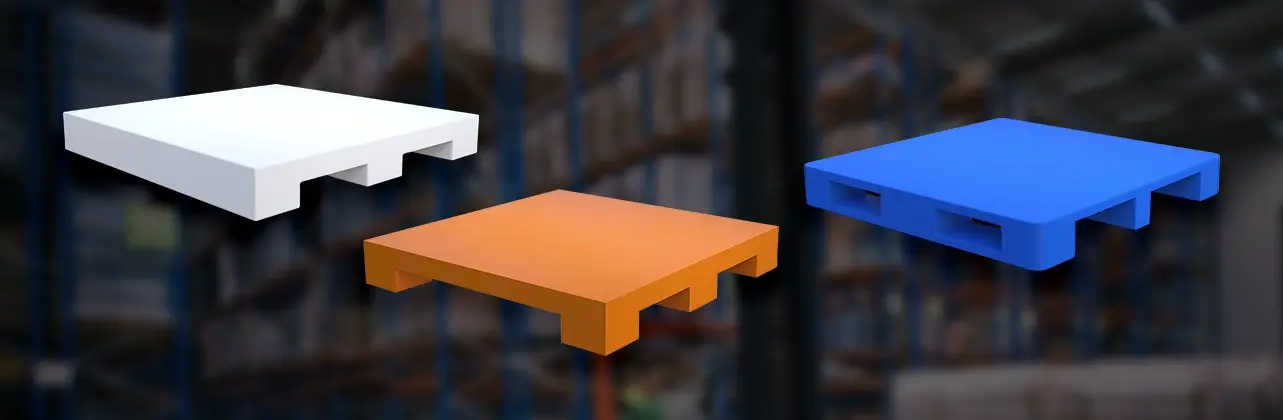

Plastic pallets are now revolutionizing the logistics and manufacturing sectors with their unmatched reliability and innovation. Durable, long-lasting solutions designed to handle industrial loads save businesses a bundle in efforts to optimize operations. Made using state-of-the-art methods such as rotational moulding, plastic pallets are flexible, weather-resistant, and chemical-proof—making them a must in many industries.

Allwin is the leading manufacturer of roto-molded plastic pallets, committed to quality and conformance to industrial standards. Its durability and hygiene have enabled Allwin to become a name businesses trust in helping them improve their supply chain processes. This guide will go in-depth into the materials, benefits, and applications of plastic pallets so that you can make an informed decision for your operational needs.

Plastic pallets are made from a variety of materials, each designed to satisfy certain industrial needs. Some of the most common materials used include:

High-Density Polyethylene (HDPE): HDPE is renowned for being strong and durable, an ideal choice for heavy-duty applications. It can also withstand extreme temperatures and not easily degenerate from chemicals, which secures its performance in the long term.

Polypropylene (PP): Known for its rigidity and lightweight properties, PP is a great material for industries that focus on efficiency. Its moisture resistance and impact resistance make it ideal for export purposes.

Recycled Plastics: For environmentally conscious businesses, recycled plastic pallets offer an eco-friendly solution. Slightly less strong than virgin materials, they are cost-effective and help reduce environmental footprint.

See Also: Spill Pallets for Every Industry

Plastic pallets are the preferred choice in industries due to their numerous benefits. Here are some key benefits:

Durability: Plastic pallets and pallet containers are designed to withstand heavy loads, impacts, and extreme weather conditions. Roto-moulded pallets, in particular, are designed to handle the rigors of industrial applications.

Hygiene and Cleanliness: Unlike wooden pallets, plastic pallets do not absorb moisture or provide a habitat for bacteria. This makes them very easy to clean and sanitize, hence suitable for food, pharmaceutical, and healthcare industries.

Lightweight: Plastic pallets are much lighter compared to wooden pallets. This significantly brings down the costs related to shipping and manual handling. Their light weight also reduces workplace injuries.

Manufactured using precise molding techniques, plastic pallets provide uniformity in size and weight. This consistency enhances compatibility with automated systems, improving operational efficiency.

Weather and Chemical Resistance: These pallets are resistant to extreme weather conditions and chemical exposure, ensuring they last long and are reliable even in tough environments.

Recyclability: These pallets are resistant to extreme weather conditions and chemical exposure, ensuring they last long and are reliable even in tough environments.

Read more: Industrial Plastic Pallet Manufacturer

Plastic pallets are available in various designs catering to different industrial needs. The main types include:

Stringer Plastic Pallets: Made from HDPE or PP, stringer pallets have two parallel runners, called stringers that provide support to the pallet structure. This kind of pallet is good for heavy-duty operations and massive weight loads.

Block Plastic Pallets: One piece, solid construction for superior strength and stability; ideal for industries that deal with bulk shipment or heavy materials.

Four-Way Plastic Pallets: These pallets can be accessed from all four sides by forklifts or pallet jacks. They are designed in a manner that maximizes the efficiency of any materials handling operation.

Two-Way Plastic Pallets: Having entry points on only two sides, these pallets are suitable for cost-sensitive industries with simple handling requirements.

Stackable Pallets: These pallets are designed to be stacked vertically to save storage space in warehouses. Features such as interlocking mechanisms provide safe and stable stacking.

Plastic pallets become indispensable in various industries, where each industry requires certain unique benefits from these plastic pallets:

Retail Industry: Lightweight and easy-moving pallets ensure easy frequent movements and a better product appearance in the stores.

Food Industry: Food-grade plastic pallets ensure hygiene and safety, eliminating contamination and meeting the most demanding industry requirements.

Pharmaceuticals and Healthcare: Chemical-resistant and sterile pallets that are imperative for the safe movement of medical supplies and equipment.

Export and Shipping: Strong yet light export-grade pallets meet international shipping regulations, such as ISPM-15. They eliminate the need for fumigation, thereby saving on shipping costs.

Warehousing and Logistics: Insulated plastic containers and pallets are designed to provide long-term storage and compatibility with automated systems, ensuring smooth operations in warehouses.

Although skids and pallets are sometimes confused as being the same thing, they are not, and their differences are conveyed below:

Learn more: India's Leading Plastic Pallet Manufacturer

Choosing the right plastic pallet is a balance of your requirement that you need to consider. Here are a few things to consider:

Load Capacity: Determine the weight your pallets must support during storage and transport.

Identify whether the pallets will be used for shipping, warehousing, or industry-specific applications.

Material: Select HDPE, PP or recycled plastic according to durability, cost and environmental targets.

Material: Select HDPE, PP or recycled plastic according to durability, cost and environmental targets.

Size and Design: Ensure the pallets are compatible with your storage systems and handling equipment.

Customization: Get custom-designed pallets to fit unique operational needs and branding objectives.

Allwin takes pride in offering a wide range of roto-molded plastic pallets tailored to meet the needs of various industries. From lightweight retail pallets to heavy-duty solutions for warehousing, Allwin delivers durable, high-quality products designed for optimal performance. Headquartered in Gujarat, India, and driven by an unwavering commitment to innovation and sustainability, Allwin has established itself as the most reliable and efficient choice for businesses seeking effective pallet solutions.

In Conclusion, Unmatched in durability, hygiene, and adaptability, plastic pallets are changing the game in the field of material handling and logistics. Whether your business is in retail, food, pharmaceuticals, or logistics, these pallets provide a sustainable, cost-effective solution for you. Allwin helps to source top-grade products that promise seamless operations and long-term value for your business.