2023-11-06

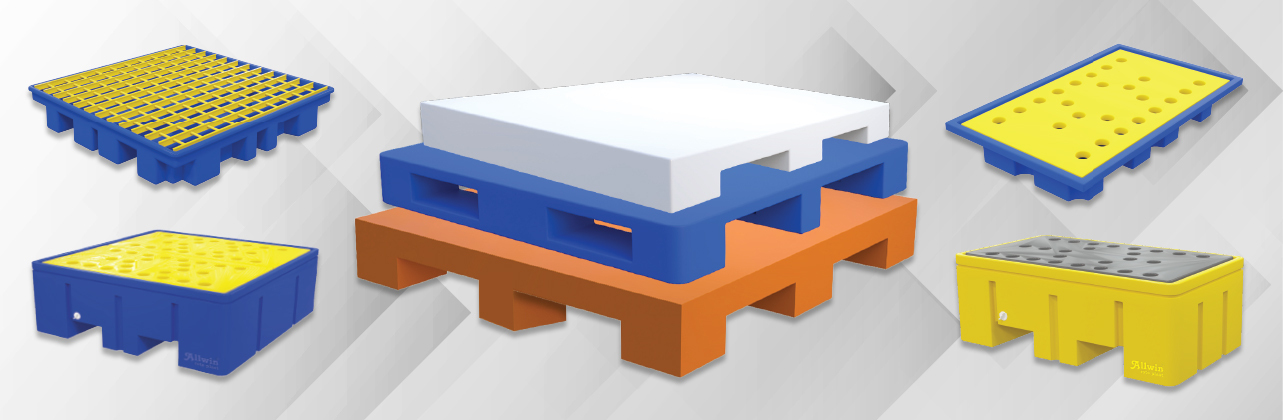

In the world of industrial safety, spill containment pallets are the unsung heroes that play a vital role in preventing environmental disasters and safeguarding the workplace. These specialized pallets, such as single-wall spill containment pallets and double-wall spill pallets, are indispensable in the storage and handling of hazardous materials. Moreover, plastic pallet manufacturers, particularly those specializing in roto-molded plastic pallets, are at the forefront of providing reliable solutions for containing spills and preventing contamination. In this comprehensive guide, we'll explore the multifaceted world of spill pallets and delve into their diverse applications, from hazardous material storage to innovative techniques like the "Kiss Of Pallet," roll pallets, and pallet configurations like the 3-runner, 4-way entry.

Spill containment pallets are an essential component of industrial safety. They are designed to contain, manage, and prevent the spread of hazardous materials in the event of a spill, leak, or drip. These pallets are a linchpin for maintaining a safe and eco-friendly working environment in various industrial settings, such as chemical plants, warehouses, manufacturing facilities, and laboratories.

Single-wall spill pallets are a versatile solution for businesses that need to store and handle smaller quantities of hazardous materials. These pallets feature a single containment wall, making them a cost-effective option for businesses with limited storage space. Available in various sizes and configurations, single-wall spill pallets are designed to meet specific requirements.

Single Wall Spill Pallets provide an effective and efficient way to contain spills, minimizing the potential harm to both personnel and the environment.

For businesses dealing with larger quantities of hazardous materials or those seeking an added layer of security, double-wall spill pallets are the ideal choice. These pallets are constructed with two containment walls, offering increased capacity for spill containment. They provide peace of mind, ensuring that even the most significant spills are effectively managed.

Double Wall Spill Pallets are a superior solution for businesses requiring enhanced spill containment and are available in various sizes and configurations.

To understand the significance of spill containment pallets fully, it is crucial to appreciate the pivotal role that plastic pallets manufacturers, like Allwin Rotoplast, play in ensuring the quality, durability, and compliance of these essential safety materials.

Roto-molded plastic pallets are a testament to the advanced manufacturing techniques used by companies like Allwin Rotoplast. The roto-molding process produces durable, robust plastic products that are well-suited for spill containment. These pallets are known for their exceptional strength, chemical resistance, and longevity, making them a top choice for hazardous material storage.

Manufacturers like Allwin Rotoplast are committed to quality control and rigorous testing to ensure their roto-molded plastic pallets meet the highest industry standards for spill containment.

Also, read: Plastic Pallets: A Good Investment During The Monsoons

Plastic Pallets from trusted manufacturers are integral in maintaining a safe working environment.

Spill containment pallets offer a multitude of benefits beyond simple containment. These versatile safety tools find application in various settings, enhancing safety and efficiency.

One of the primary applications of spill containment pallets is the storage of hazardous materials, such as chemicals and oils. These substances require specialized containment to prevent accidental spills or leaks. Spill pallets provide a compliant and safe solution for storing hazardous materials, ensuring that any spills are contained and do not pose a threat to the environment or personnel.

The "Kiss Of Pallet" technique is an innovative approach to spill containment. It involves strategically placing spill containment pallets beneath drums, containers, or other storage units. This practice minimizes the risk of contamination in case of leaks or spills. The "kiss" of the pallet enhances safety, simplifies the cleanup process, and reduces the potential for workplace accidents and environmental damage.

Roll pallets are specialized spill containment equipment designed for easy maneuverability. These pallets come equipped with built-in wheels, allowing for the effortless movement of drums and containers. This feature is particularly valuable in busy industrial environments, where materials need to be repositioned or relocated frequently.

Spill pallets are available in various configurations, including the 3-runner, 4-way entry design. The 3 runner design offers stability and support, while the 4-way entry design allows for easy forklift access, simplifying pallet handling and storage.

In a world where the spotlight often falls on high-profile industrial equipment, it's essential to recognize the uncelebrated heroes who quietly ensure safety and efficiency. Spill containment pallets, available in both single-wall and double-wall configurations, play a pivotal role in containing hazardous materials, preventing environmental contamination, and streamlining the cleanup process.

The expertise of plastic pallet manufacturers, like Allwin Rotoplast, in producing high-quality roto-molded plastic pallets is instrumental in the success of spill containment systems. Their commitment to product quality and compliance with industry standards ensures that businesses can rely on spill containment pallets to perform effectively.

Contact Us today to learn more about how Allwin Rotoplast can help you optimize safety in your industrial operations.